Menu

Your cart is empty

Looks like you haven't added anything to your cart yet

LCD PID temp readings

Clear and easy to read

Easily see your temperatures and set them with our EBSP200 PIDs. Solid, stable, reliable, and easy to use. No convoluted menus to navigate.

POWER RATING

Standard or Double Batch

Brew with 1 vessel at a time or 2. With double batch power, heat your HLT and Boil kettles at the same time; speeding up your day. Prepare the second batch of strike water or clean up more quickly.

See the specifications for power draw for each power rating.

INCLUDED

Probes included

Included in the price is our high quality RTD/PT100 probes. Select between 1/2 NPT threaded probes or 1.5" Tri-Clamp probes.

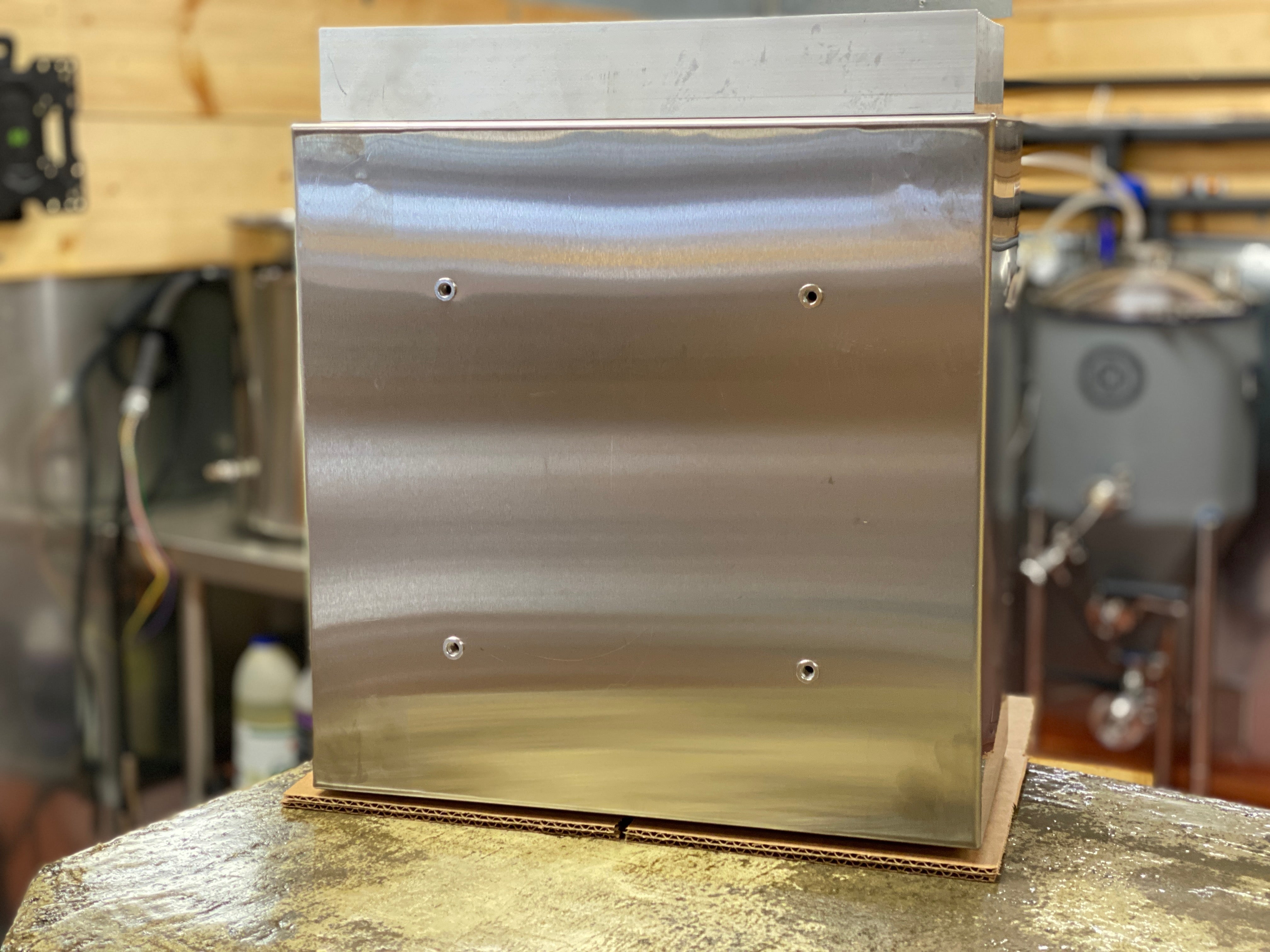

Easily mounted

Mount your panel quickly using an industry standard 200x200 VESA TV wall mount. No more guess work involved, find your stud, mount the wall bracket and then, your panel.

Proudly made in the USA

All of our control panels are made right here in the USA. With support and technical help provided by the same folks who designed and built the panel for you.

Recommended for You

- Choosing a selection results in a full page refresh.